Understanding the Dosing Pump Market and Its Global Growth

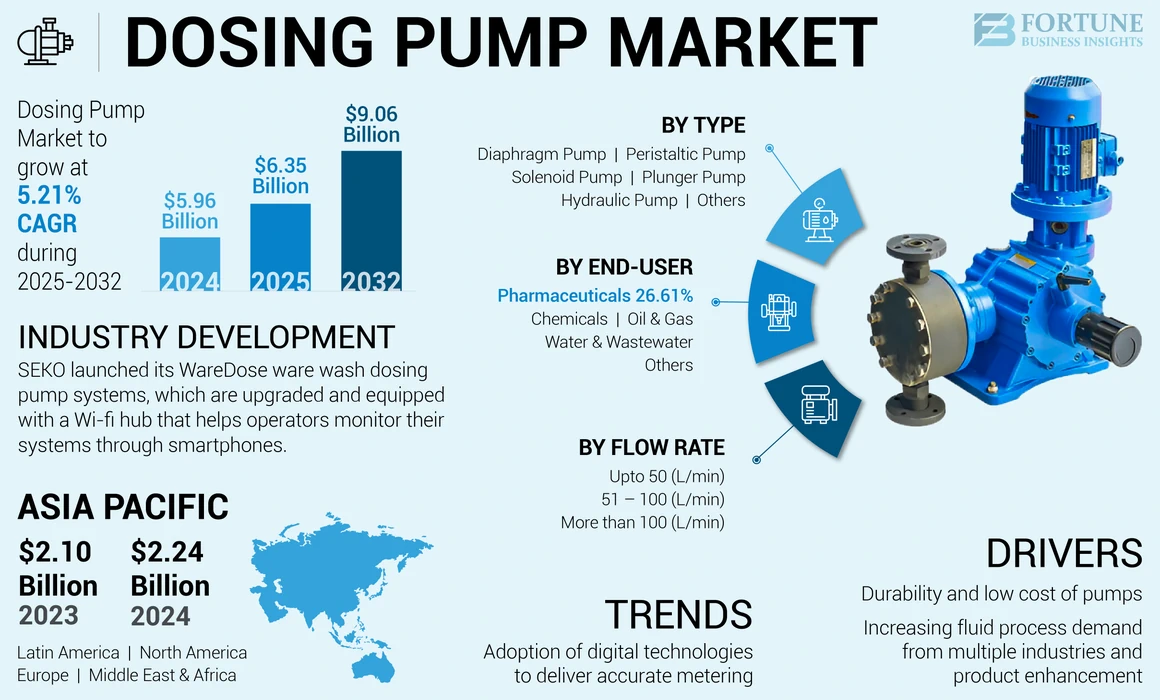

The dosing pump market is currently experiencing a significant upturn with forecast figures projecting a rise from USD 9.3 billion in 2025 to USD 15.6 billion by 2035. This expansive future is underscored by a compound annual growth rate (CAGR) of 5.3%. As we take a closer look at this sector, it becomes clear that precision in chemical injection and fluid handling systems is a must-have feature in various applications—ranging from municipal water treatment to industrial chemical processes. In this editorial, we aim to offer an unbiased view of the evolving dosing pump market, address its promising opportunities, and outline the tangled issues that companies may face as they work through the market’s twists and turns.

With key players including ProMinent Group, Grundfos Holding A/S, and Watson-Marlow Fluid Technology Solutions driving the market, the increasing focus on precision chemical delivery and process automation is shoring up the need for advanced dosing pump solutions across many industries.

Water Treatment Infrastructure Expansion in Emerging Markets

One of the standout forces fostering this market’s growth is the surging demand for enhanced water treatment infrastructure. Municipal water treatment is not only pivotal for public health but also for meeting environmental compliance requirements. Investments in upgrading potable water systems and wastewater treatment facilities are offering dosing pump manufacturers tremendous opportunities to expand their operations and enhance their product lines.

In emerging markets such as India and China, government-backed projects in water infrastructure are critical. India, for instance, is projected to lead the growth at a CAGR of 6.8% until 2035. This momentum is a result of several factors, including:

- Robust government infrastructure development programs

- Increased allocation for municipal water treatment upgrades

- Focus on enhancing chemical injection precision to reduce wastage

With significant investments in water infrastructure, these regions are witnessing a surge in the demand for dosing pump systems that cater to both water and wastewater treatment needs. This targeted expansion not only promises improved operational performance but also positions local manufacturers as key players in the global supply chain.

Advanced Dosing Pump Innovation in Industrial Manufacturing

Industrial manufacturing is another arena that is reaping the benefits of advanced dosing pump technology. In sectors such as chemical processing, pharmaceutical manufacturing, and food & beverage production, the accuracy and reliability of chemical metering are super important. Modern dosing pumps typically offer 30-50% better accuracy and chemical utilization compared to conventional systems.

This improvement is credited to innovative designs like diaphragm pumps, which currently dominate the market with a share of approximately 55.7%. Within the diaphragm pump category, solenoid-driven systems enjoy widespread adoption due to their superior electromagnetic actuation and precision control capabilities. These pumps effectively address the tricky parts of chemical injection by ensuring leak-free operation and efficient chemical delivery.

Industrial manufacturers are increasingly turning to such advanced dosing pump solutions to optimize their processes. Reduced chemical consumption, improved accuracy, and better process control contribute significantly to lowering operational costs while conforming to environmental standards.

Smart Dosing Pump Systems Integration and IoT Capabilities

In today’s digital age, integrating dosing pumps with smart, IoT-enabled systems is turning out to be a game changer. By embedding advanced digital controls, remote monitoring, and predictive maintenance protocols, these systems help industrial operators get into the nitty-gritty of process optimization.

Features including real-time flow tracking, automated chemical optimization, and integrated process analytics empower companies to make data-driven decisions. With a smart dosing pump system in place, a facility can seamlessly figure a path through the complex maze of process management while reducing downtime and maintenance costs.

This technological advancement is not just about the seamless operation of equipment—it is also about leveraging connectivity to offer better control and a more responsive operational framework. As companies look to modernize their dose injection systems, the importance of technology that can integrate well with industrial automation platforms is becoming ever more pronounced.

Impact of Government Regulations and Environmental Directives

Government initiatives and environmental regulations are among the key drivers spurring dosing pump market growth. Authorities around the globe are introducing streamlined approval processes and stricter discharge standards that force water utilities and industrial operators to improve their chemical dosing practices.

These policies encourage investments in advanced dosing pump systems that can offer more precise chemical delivery, thereby lowering overall process inefficiencies. Regulatory frameworks set by governments are not meant to be intimidating; rather, they help foster an environment where technological innovation can thrive and contribute to better water quality management.

A quick overview of government support in this domain includes:

- Water infrastructure programs with funding for municipal facility upgrades

- Tax incentives for utilities that adopt advanced dosing systems

- Support for industry bodies to define standardized performance metrics

The interplay between government actions and private investments is creating a conducive environment for advanced dosing pump innovations, resulting in improved safety, better chemical utilization, and enhanced process control in water and wastewater sectors.

The Role of Diaphragm Pumps within the Dosing Ecosystem

Among the various dosing pump types, diaphragm pumps have cemented their foothold within industrial applications. Their ability to manage corrosive chemicals and offer precise control makes them a favorite in industries ranging from municipal water treatment to pharmaceutical processing. With a current market share of about 55.7%, these pumps provide a stable foundation for even more sophisticated chemical handling systems.

Key advantages of diaphragm pumps include:

- Superior chemical resistance

- Consistent metering precision

- Leak-free operation due to hermetic seal designs

- A well-established reputation in variable dosing applications

The subcategory of solenoid-driven diaphragm pumps, which holds a 62.0% share within this segment, exemplifies the industry’s move towards electrified, precision dosing technologies. These solutions have gained popularity due to their ability to control dosing parameters through electromagnetic actuation—a design that significantly reduces the confused bits associated with conventional systems.

Assessing the Opportunities in Chemical and Pharmaceutical Processing

The dosing pump market’s influence extends well beyond water treatment. In the chemical and pharmaceutical industries, precision is not just preferred—it is essential. The need for controlled chemical injection in manufacturing processes is critical, as even minor deviations can have significant effects on product quality and process reliability.

Pharmaceutical manufacturers, in particular, require systems that maintain rigorous standards for accuracy and repeatability. This has led to a growing reliance on dosing pumps that are both robust and capable of handling sensitive chemical reactions. Similarly, chemical processing plants are increasingly investing in dosing pumps to tackle the nerve-racking aspects of precise catalyst and reagent injection.

Industrial operators in these sectors favor dosing pump systems that can provide:

- Superior safety protocols

- Reliable performance even in harsh, corrosive environments

- Enhanced chemical optimization to reduce waste and lower costs

Such incremental advancements allow companies to manage the subtle parts of their manufacturing processes better, ensuring that product output remains of high quality and that operational costs are kept in check.

Regional Market Dynamics and Country-Level Growth

The dosing pump market is marked by regional dynamics that vary considerably across the globe. From an opulent landscape in North America and Europe to rapidly expanding infrastructure ventures in Asia Pacific and Latin America, the market’s growth is a collaborative result of local strategies and global technological progress.

Below is a simplified table illustrating the projected compound annual growth rate (CAGR) for key countries in the dosing pump market from 2025 to 2035:

| Country | CAGR (2025-2035) |

|---|---|

| India | 6.8% |

| China | 6.6% |

| Brazil | 5.9% |

| USA | 4.8% |

| Germany | 4.6% |

| UK | 4.3% |

| Japan | 3.9% |

This table underscores the importance of regional market trends, notably the exciting growth in emerging economies where infrastructure development and local government support are key enablers. For instance, India’s dedication to Make-in-India initiatives and expansive water treatment projects provides an excellent case study in how regional focus can propel the entire market forward.

Industrial Process Automation and the Rise of Precision Metering

Industrial process automation is driving many operators to adopt automated dosing pump systems. This evolution is a direct result of the need to get around the more confusing bits of manual chemical injection processes. By automating dosing, companies can achieve far higher precision and significantly lower operational costs.

An integral aspect of this trend is the adoption of smart dosing solutions that integrate with industrial control systems. These platforms provide operators with real-time data, thus enabling them to make timely decisions that enhance efficiency and ensure greater safety. Key benefits of moving to an automated system include:

- Reduced manual intervention and error risk

- Better chemical efficiency with improved accuracy

- Ability to handle process fluctuations with minimal constant adjustments

- Enhanced connectivity with remote monitoring tools

This integration of smart dosing solutions represents not just a technical upgrade but also an important shift in operational philosophy. Companies are increasingly realizing that to remain competitive, they must invest in systems that support digital transformation and process automation.

Overcoming Technical Challenges and High Initial Costs

Despite the promising outlook, the dosing pump market is not without its tangled issues and intimidating challenges. One of the primary obstacles is the high initial capital investment required for these advanced systems, which can be off-putting for smaller operations or regions with limited financial resources.

Handling corrosive chemicals presents another layer of tricky parts. Specialized equipment must be utilized to manage these harsh substances safely—often involving advanced materials and design techniques. The technical support and maintenance of these systems also become nerve-racking for operators who might not have access to skilled technicians.

Nonetheless, manufacturers are actively working through these challenges by:

- Developing cost-effective solutions that retain high precision.

- Investing in training programs to increase the availability of skilled technicians.

- Enhancing equipment durability through advanced materials and robust design approaches.

These strategies help companies not only figure a path through the complex financial and technical pieces but also ensure that the dosing pumps provide long-term value in demanding environments.

Market Segmentation: By Type and End Use Applications

To truly understand the dynamics of the dosing pump market, it helps to take a closer look at its segmentation. The market is divided primarily by pump type and the end-use applications.

By Type, the market includes:

- Diaphragm Pumps

- Peristaltic Pumps

- Piston/Plunger Pumps

- Others

Diaphragm pumps, as discussed earlier, lead the field thanks to their superior chemical compatibility. The peristaltic pump segment, holding a 22.0% market share, is especially popular in the pharmaceutical and food industries due to its hygienic and zero cross-contamination properties. Then there are piston or plunger pumps, which are especially useful in high-pressure applications like oil and gas, accounting for roughly 16.0% of market share.

By End Use, the key applications include:

- Water & Wastewater Treatment

- Chemical Processing

- Pharmaceutical Manufacturing

- Food & Beverage Production

- Oil & Gas Applications

- Others

Municipal water treatment stands out as a super important application, commanding around 23.2% of market share overall, with municipal facilities often leading investment initiatives due to the high priority placed on ensuring public water safety.

Integrating Dosing Pumps with Modern Process Control Systems

The growing emphasis on digital transformation in industrial environments is a key reason for the move towards smart dosing pump systems. Operators are increasingly taking the wheel by integrating these pumps with advanced process control systems to lower maintenance costs and boost productivity.

This integration is characterized by:

- Real-time flow monitoring that enhances operational transparency

- Predictive maintenance features that help manage equipment reliability

- Remote control capabilities that assist with precise dosing adjustments remotely

- Data analytics that support continuous process optimization

By merging traditional dosing technology with modern digital tools, manufacturers are offering solutions that are designed to solve both the tangible and subtle parts of industrial process challenges. These systems enable industrial facilities to work through the complicated pieces with greater ease and reduced risk downtime.

Balancing Innovation and Conventional Processes in a Mature Market

While innovation rapidly transforms the dosing pump landscape, the market still harbors reliance on conventional dosing solutions in certain segments. This is understandable given that traditional systems have long-established reputations for reliability. Yet, as the demand for efficiency and precision grows, even these long-standing solutions are being enhanced with new materials and smart-control features.

In balancing innovation with legacy systems, companies face a few key tasks:

- Modernizing existing equipment to keep pace with digital advances

- Expanding system capabilities without overwhelming operators with the technical bits

- Leveraging proven technologies while integrating incremental upgrades for cost efficiency

Industry insiders acknowledge that merging innovative digital controls with reliable dosing pump systems is more than just a technical upgrade—it is a strategic imperative. The benefits extend from improved process automation and accuracy to long-term cost savings, offering a robust competitive edge in a market that is rapidly evolving.

The Competitive Landscape and Future Outlook

The dosing pump market exhibits moderate concentration with a mix of both large multinational organizations and emerging local players. The competition is primarily based on the overall portfolio strength, product reliability, technical after-sales services, and successful integration with industrial process control systems.

Key market leaders such as ProMinent Group, Grundfos Holding A/S, and Watson-Marlow Fluid Technology Solutions maintain their competitive stance through continuous innovation and strong distributor relationships. Meanwhile, emerging challengers like Netzsch Pumps and SEKO S.P.A. have successfully found ways to figure a path through the crowded marketplace with specialized product approaches that cater to niche applications.

This competitive mix pushes the entire industry towards a future where technological innovation and high-precision dosing are not just competitive elements—they are essential for survival. The trends indicate that investment in advanced digital controls and integrated systems is crucial for those looking to secure a market-leading position well into 2035.

Looking ahead, the market is likely to witness further growth driven by:

- Continued industrial automation and adoption of smart dosing systems

- Expansion in emerging economies with significant infrastructure investments

- Focused research in advanced materials and sensor technologies to improve efficiency

- Greater alignment with evolving environmental regulations globally

These factors encourage a balanced approach where technological evolution and time-tested design principles work hand-in-hand to meet increasing global demand.

Opportunities for Investors and Financial Enablers

For investors and financial enablers, the dosing pump market presents attractive opportunities. The steady market growth and the emphasis on technological innovation are clear signals of a robust investment climate. Capital infusion in this space is not only about funding advanced product development but also about supporting regional market expansion and strengthening manufacturing capabilities.

Investment opportunities are bolstered by the following factors:

- Rising demand for municipal water treatment solutions in rapidly urbanizing regions

- Technological advances in IoT-enabled dosing pumps that promise higher operational efficiency

- Strategic acquisitions and consolidation moves that can streamline production and distribution

- A highly supportive regulatory environment in major markets such as India, China, and Europe

Investors are increasingly paying attention to companies that demonstrate capability in not only advancing dosing technology but also in providing comprehensive support and service networks. Growth capital focused on scaling production, research, and market expansion could prove a significant driver in further cementing the position of established players and accelerating the emergence of smaller, local champions.

Looking at the Broader Economic Impact

Beyond the technological and operational facets, the dosing pump market also plays a critical role in the broader economic landscape. By optimizing chemical dosing, facilities can reduce their operating expenses while boosting process efficiency. This has a multiplier effect on economic growth, particularly in industrial hubs that rely heavily on manufacturing and process automation.

Additionally, the adoption of advanced dosing pumps contributes to improved environmental outcomes. Better chemical utilization translates to reduced chemical wastage and lower environmental impact, aligning industrial growth with sustainable development goals. In turn, this helps companies mitigate risks related to environmental compliance and secure long-term operational stability.

The economic benefits further extend to associated industries, including:

- Industrial equipment manufacturing and supply chain services

- Professional training and technical support sectors

- Software and data analytics firms focused on process control systems

Through its impact on operational efficiency, cost control, and environmental sustainability, the dosing pump market is not an isolated industrial niche—it is a vital component of the larger economic engine powering industrial innovation and growth worldwide.

Key Takeaways and Future Outlook

In summary, the dosing pump market is poised to traverse an expansive growth trajectory over the next decade. With market projections indicating an increase to USD 15.6 billion by 2035, the sector offers ample opportunities for innovation, investment, and operational efficiency enhancements. Several core themes form the foundation of this market’s future:

- Technological Innovation: Advancements in diaphragm pump technology and IoT-enabled dosing systems are transforming process automation and enhancing metering precision.

- Government and Regulatory Support: Increased government investment in water infrastructure and tighter environmental compliance requirements are acting as catalysts for market growth.

- Regional Dynamics: Emerging markets, especially in India and China, are leading the way in terms of growth potential, further stimulating global expansion.

- Investment Opportunities: The market presents promising avenues for investors focused on both advanced product development and strategic market consolidation.

- Economic and Environmental Impact: Enhanced process efficiency in chemical dosing leads to reduced operational costs and better environmental outcomes.

As industry players continue to innovate and invest in smart, automated systems, the dosing pump market is set to become even more critical as a backbone for industrial process control. Stakeholders—ranging from technology developers to municipal authorities—must work together to overcome the tricky parts of high initial costs and technical challenges, ensuring that the benefits of innovation are accessible across the board.

A Collaborative Path Forward

Looking to the future, a collaborative approach will be essential for sustaining the market’s expansion and reaping the benefits it promises. Government bodies can spur local development by promoting policies that encourage infrastructure modernization and provide financial incentives for equipment upgrades. Likewise, industry bodies and technology providers should work in tandem to establish performance standards, offer professional development, and foster innovation in dosing pump technology.

A coordinated strategy across the following areas is seen as essential:

- Equipment Standards & Certification: Clearly defined performance metrics to ensure reliability and operational consistency.

- Market Education & Best Practices: Disseminating success stories and best practices that highlight the tangible benefits of advanced dosing technology.

- Technology Integration: Developing standardized interfaces for integrating dosing pumps with SCADA systems and other industrial control platforms.

- Training & Skills Development: Investing in vocational programs to prepare the workforce for the increasingly digital and automated industrial landscape.

This collaborative pathway, backed by thoughtful government policy and proactive industry initiatives, is expected to mitigate the nerve-racking aspects of transitioning towards advanced dosing systems and pave the way for sustained market growth.

Conclusion: A Bright Future Full of Promise

The dosing pump market is at a crucial juncture. As sectors ranging from water treatment to chemical processing continue to modernize, the shift towards precision dosing offers a strategic advantage that could redefine industry best practices. The market’s steady growth, combined with emerging opportunities in digital automation and IoT integration, provides a robust framework for future success.

Despite the intimidating high initial costs and technical challenges that many players currently face, the pathway forward is illuminated by continuous innovation and collaborative initiatives among manufacturers, technology providers, and governmental agencies. Facilities that invest in these advanced dosing solutions stand to benefit from improved efficiencies, lower operational costs, and enhanced compliance with environmental standards.

In this dynamic landscape, it is clear that the trends shaping the dosing pump market will have a broad and lasting impact, not only on industrial process control but also on the overall economic and environmental health of industries worldwide. As we make our way through these evolving twists and turns, the collective vision of a more efficient, connected, and environmentally responsible industry becomes increasingly attainable.

Ultimately, the dosing pump market exemplifies how technology, when judiciously applied, can resolve tangled issues and improve operational clarity. With the right mix of innovative products, supportive policies, and dedicated industry collaboration, the future is set to be a promising one—full of opportunities for all stakeholders involved.

Originally Post From https://www.factmr.com/report/dosing-pump-market

Read more about this topic at

Dosing Pump Market Size & Share | Global Growth [2032]

Dosing Pump Market Size & Outlook, 2025-2033